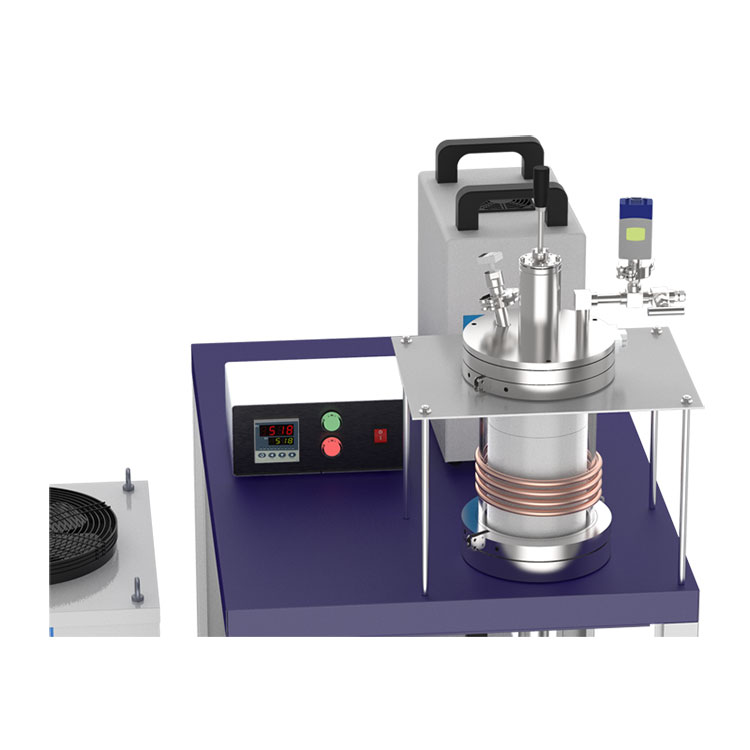

Induction Heater | Working Voltage: 220V AC, 50/ 60Hz, Three Phase Working Current: 5~52 Amps (a 60A breaker is required) Max. Input Power: 15 KW

Output Frequency: 30 - 80 kHz Duty Cycle: 80% Induction Coil: 170mm(OD) x 155mm(ID) x 110mm(H) Protection: automatic water pressure, over temperature, and overpower protection

|

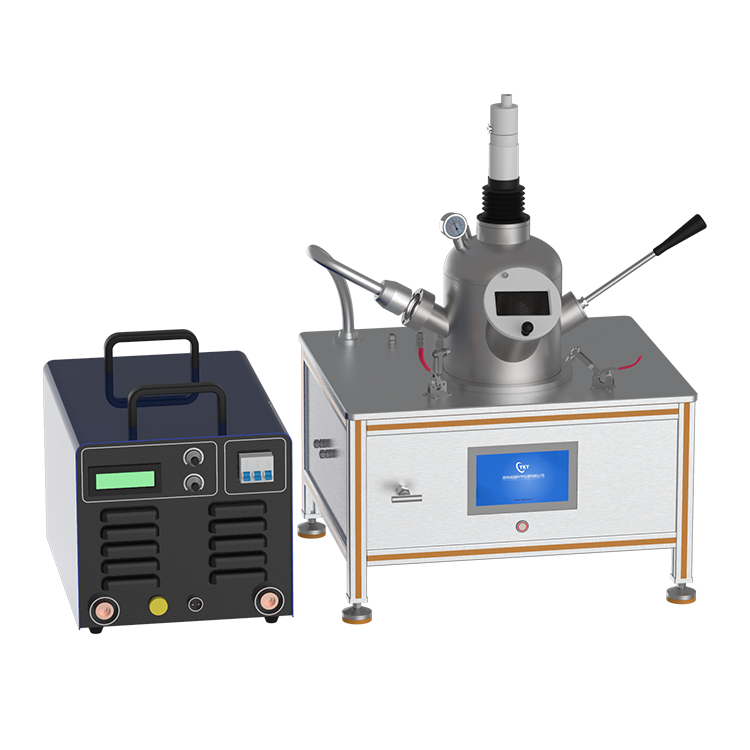

| Material Feeding & Melt Stirring | A Φ50×120H mm quartz ante-chamber was installed on the top of the main chamber for sequentially adding source materials into the crucible

without breaking the vacuum or atmosphere of the main chamber. Such a unique feature provides the opportunity for preparing metal alloys

with compositions of different melting points. The SS retractable stirring rod can reach and stir the melt inside the graphite crucible (stirring rod with alumina tip is available upon request, the additional cost will apply.) A gate valve is employed for isolating/open the ante-chamber from/to the main chamber when material adding or melt stirring are needed. Material feeding port and tipping over tray diameter: Φ30

|

Graphite Crucible, Refractory liners & Protective Shield | High Purity Graphite Crucible: 73 O.D × 63 I.D × 140 Hmm is included for induction heating and metal smelting. Max. Loading Capacity: 200ml Refractory assembling: complete refractory assembling made of alumina, including bottom crucible support, crucible holder, and cover. PVC protective shield is included

|

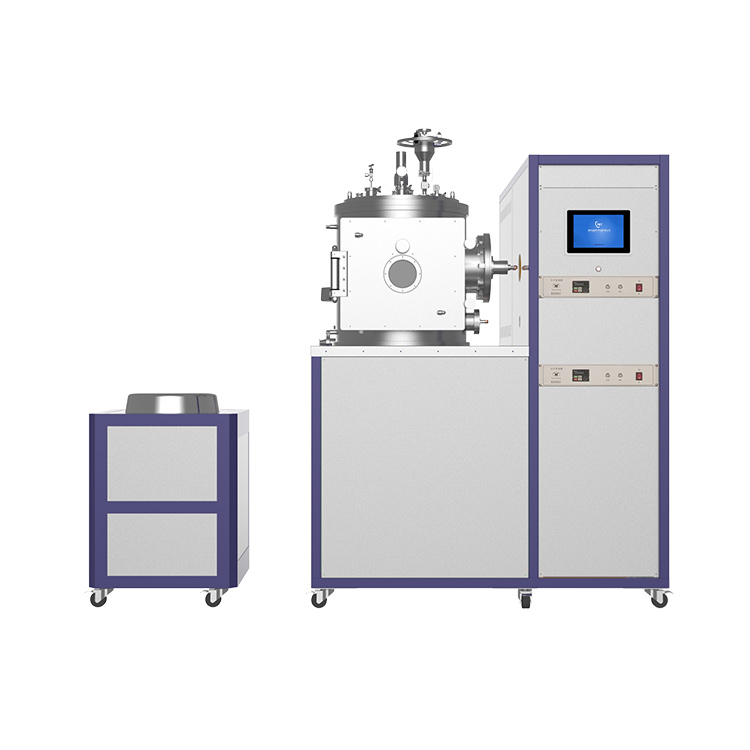

Sealing Flanges & Quartz Chamber | 150mm(OD) x 142mm(ID) x 400mm(L) Quartz furnace tube is included Top Flange: 6'' Stainless steel water cooled flange with 1/4'' thermocouple feedthrough, antechamber, needle valves, and a gate valve. Bottom Flange: 6'' Stainless steel flange with a pressure relief valve, a needle valve and KF-25 vacuum port. KF25 right angle valve & clamps and 1000mm long SS bellows are included for connecting to vacuum pump. The pressure relief valve is designed to release pressure at 0.02MPa for safety concerns.

|

Temp. Controller & Thermocouple | Precision digital temperature controller with automatic PID tuning. 30 segments programmable for controlling heating and cooling rate as well as dwell time. Overheating & thermocouple failure protection. +/- 3℃ temperature accuracy. Thermocouple: C type (1/4"x16" L) Continuous Working Temp. Range: 800℃~1700℃ Max. Heating Rate:

|

Pressure Sensor | Anti-corrosive capacitance diaphragm gauge (Gas Independent), measurement range up to 3.8x10E-5 torr One 24V,1A DC power adapter is included and ready to use. Input voltage for the adapter is 110~240V Single Phase.

|

Water Chiller | |

Vacuum Pump | One 156 L/min Double Stage Rotary Vane Vacuum Pump is included. Max. Power Consumption: 400W If you choose high-speed turbo-pump, vacuum level can reach 10- 6 torr

|

Product Dimensions | Induction Heater: 51"(L) x 27.5"(W) x 70"(H) (1300mm x 700mm x 1800mm) Water Chiller: 18"(L) x 18.7"(W) x 30"(H) (460mm x 475mm x 762mm) Heavy Duty Mobile Cart provides 600mm(L) x 800mm(W) surface for placing Induction Heater & Quartz Tube with Flange

|

Warranty | One year limited warranty with lifetime support Consumable parts such as processing tube, refractory liners, o-rings and heating coil are not covered by the warranty

|

Net Weight | |